SUSTAINABILITY

Can printing be eco-friendly?

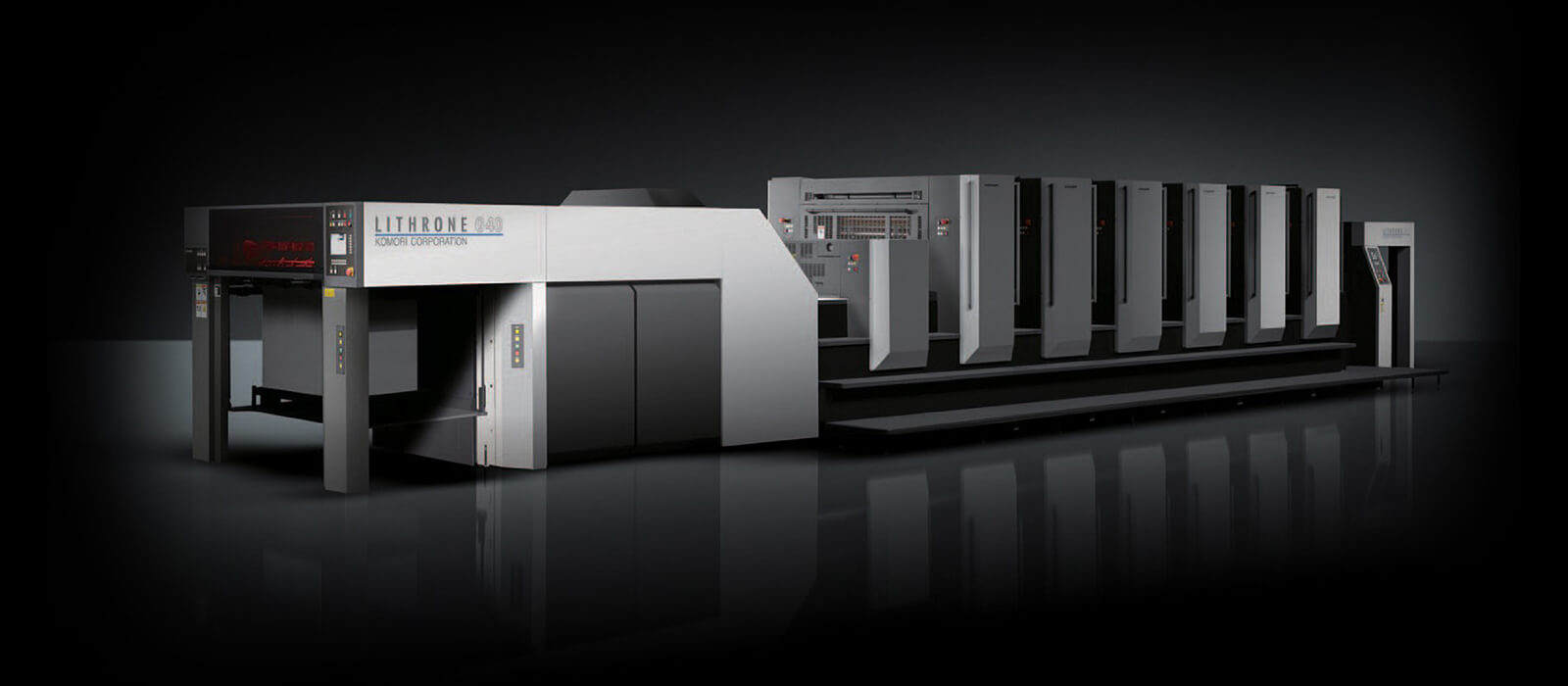

If environment matters for you, then your choice is HUV printing. Being eco-friendly printer is not only about using the FSC, or recycled paper, but also being responsible for use of electricity, inks and recycle of waste. HUV technology brought printing to the new level. A single HUV lamp can cure up to 400% ink coverage plus coating at maximum press speed – reducing energy required for curing, lowering heat output, and omitting no ozone or odours, making the environment more enjoyable for staff.

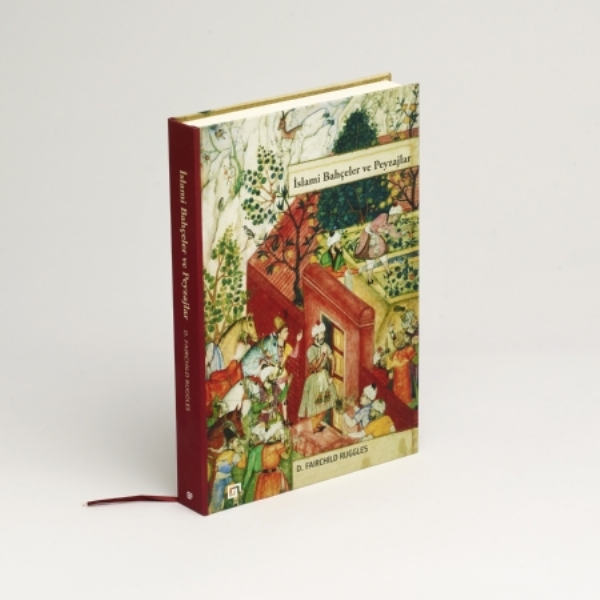

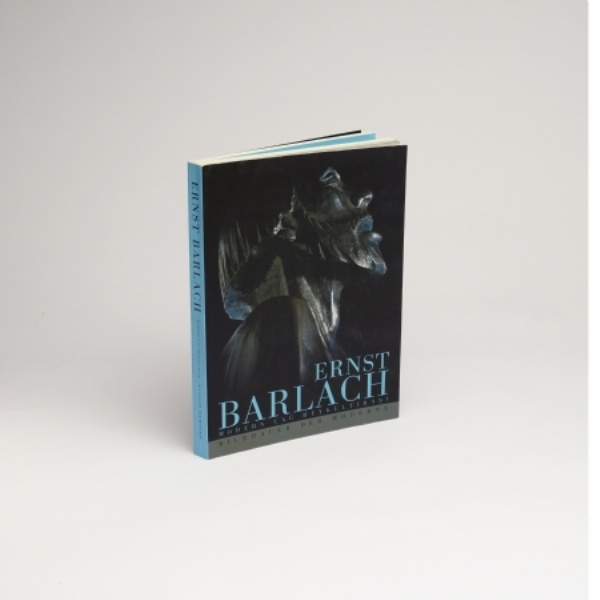

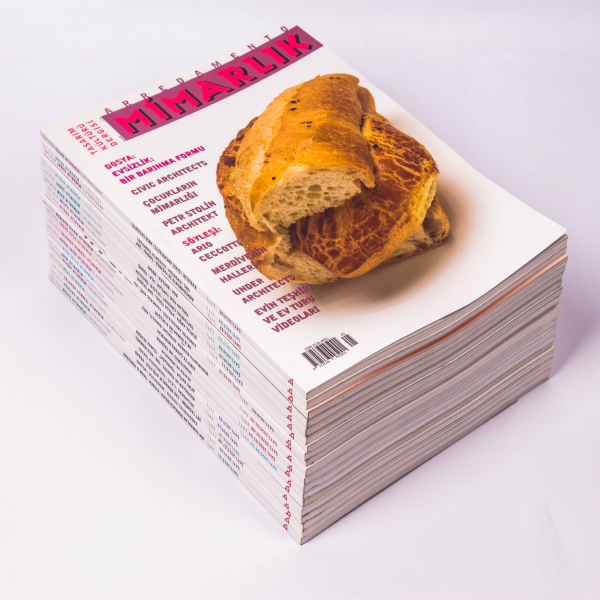

This technology allows your printed sheets to be immediately dry. Moreover, HUV inks give sharp and live colours not only on matt and gloss stock, but what is more important on uncoated paper too. The inks dry immediately, using fewer lamps and less energy, and leave great images to admire.

VERDICT – HUV is environment friendly printing that leaves the colours so bright and intense that you cannot take your eyes off the images.

What is HUV ?

HUV is the new generation of Litho Printing.

I am sure you are aware of the problems that often appear in the lithoprinting. Of course these are markings, or setoffs, excess use of powder, and dull imagery on uncoated paper.

Markings, set-offs – Oil based inks need time to dry. After the printing is finished and the sheets are left to dry the wet ink transfers to the reverse side of the sheet. In order to avoid it, printers use powder.

Powder – Using spray powder is often overlooked. It may bring to the unexpected results. Excess of powder will end up with a rough surface, as it settles in the ink and leave residue all over the sheet.

Dull imagery on uncoated paper – Using uncoated paper in printing may be very tricky. Colours may look fantastic at the moment of printing. However, in the short time the inks soak into the surface of the paper and make the images flat and dull.

Is there a chance to avoid it? No, unless you use HUV printing. Here is a brief summary about the technology and its strong points.

HUV technology brought the end to the above problems. First, the UV light instantly dries the ink to ensure mark free print. Ink dries on the surface so the colour you see in the printing is the colour you get in the finished product. With LightCure technology, there is no longer a need for spray powder. The superior finished product is waiting for you. Bright and vibrant images can be printed now on any surface.